Bioplastics and Dissolvable Plastics for eCommerce Packaging

Updated April 19, 2024 • 44 minute read

Table of Contents:

- Overview

- What is a Bioplastic?

- Biodegradable versus Compostable

- When should Bioplastics be Utilized?

- We Prioritize Recycled Content as our #1 Input Material

- Why Bioplastics are an Appealing Option

- Our Analysis

- Tools and Resources

- Mythbusting & The Bigger Questions

- Carbon Footprint of Packaging

- Should Plastics Meant for the Landfill be Biodegradable?

- Consumer Access to Composting in the United States

- The Role of Water Treatment in Packaging Disposal

- Cautionary Tales, Discernment, and our Responsibility to Water

- PVOH Review

- Our Framework for Sustainable Bioplastics Analysis

- An Ideal Bioplastic

- Recommendations for Ongoing Learning

- Bibliography and Sources

Overview

Introduction

EcoEnclose is a leading provider of sustainable eCommerce and shipping packaging. We commit to the thorough research, vetting, and consistent improvement of every packaging solution we offer. This resource aims to provide a recent and updated review of the market and the potential of bioplastics as a potential addition to the portfolio of eCommerce packaging materials. eCommerce has increased in the last three years and has brought a comparable demand for packaging.

We published our first comprehensive guide to bioplastics in 2018. So it’s time to reassess what’s out there!

This resource aims to empower you to be an informed consumer and tackle the following three main topics:

Understanding what biopolymers are on the market.

What questions to ask when sourcing materials.

Making sense of the complex and nuanced use cases of biopolymers.

Matrices 1, 2, and 3 house most of the information researched and found relevant for each material. Use these for ongoing reference. The remainder of this resource focuses on contextualizing these materials into our existing systems and sustainability choices.

A Note from the Author

Bioplastic is an area of rapid development. Eco-conscious businesses and consumers are eager to find a solution to critical problems that have become front of mind to citizens of the planet: plastic ocean pollution, reliance on fossil fuels as inputs of our packaging, carbon emissions, and landfill waste. In many ways, biopolymers seem like they could be just the right solution to all or many of these problems.

Bio-, biodegradable, compostable have all taken on the similarly confusing and inconclusive nature of the other profitable adjectives of the decade: organic, eco, natural, sustainable, circular, regenerative, etc.

Given my background, it seems like I should be able to understand biopolymers reasonably quickly. I have a degree in environmental sustainability. I have been taught various environmental remediation methods, like wastewater treatment - both industrial and municipal- air emissions management and hazardous waste. I have hands-on experience in waste diversion, zero-waste design, and vermicomposting. I’ve managed carbon accounting and greenhouse gas inventories. At EcoEnclose, I research new materials on the market, and how they interact with the waste streams and systems we have in the United States to learn how and if they will play well together. I think about packaging for 40 hours per week, minimum.

And yet.

When researching biopolymers on the market and even the definitions of the term biodegradable (it turns out there are several, with no accurate regulation to defer to), I confess that I found myself (several times) on the floor of my office, limbs sprawled and eyes glazed at the ceiling - attempting to reconcile varying definitions, applicability, use-cases, and reasonable environmental implications.

Not to mention trying to make sense of the more significant question: are these polymers any better than petroleum-based plastics?

Suffice it to say; this was not easy. However, completing this research has reiterated the complexity of the bioplastics world.

All this to say, if you are confused by the bioplastics world, you are not alone. It is incredibly complex, and your confusion points to an important takeaway: these are materials with no existing regulation or impartial authority.

I hope the resource I’ve put together, the result of my deep dive into the complexities of this space, is helpful for you. It aims to save you time, build clarity, and help guide your business toward data-driven sustainable packaging decisions.

I welcome all feedback, questions, and suggested additions to this research. Feel free to contact me!

Sarah Quirk

sarah@ecoenclose.com

Sustainable Innovations Lead, EcoEnclose

Materials Reviewed (Scope)

The following biopolymers were researched and reviewed in this resource:

- PVOH / PVA (dissolvable)

- Corn Starch Foam (dissolvable)

- Biodegradability additives

- Bio-PE

- Bio-PET

- PLA + PBAT

- PBS

- PHA / PHB

- PEF

- Cellophane

Products not included in this review:

- Bioplastics that we know will never be relevant for eCommerce packaging.

- Why? EcoEnclose is a leading provider of eCommerce and shipping packaging. Thus, our research focuses primarily on applying materials in this space. We’ve reviewed bioplastics and materials advertised for application in eCommerce or used currently in this space.

- Fiber-based compostable packaging

- Food-grade, to-go containers, paper, or fiber-based cutlery or dishes.

- Why? These are 1.) outside of our scope and relevance, and 2.) These materials are not considered bioplastics (synthetically-produced polymers) by nature - they are fibrous.

- Silicone

- Why? We consider this to be a standard plastic.

- Oxo-Degradable or Oxo-Biodegradable Plastics

- Why? EcoEnclose does not consider these bioplastics since they are not derived from bio-based materials, biodegradable or compostable. They encourage misguided consumer actions (either littering plastic or composting plastic in a way that contaminates industrial composting facilities). They have unknown and potentially harmful impacts on the recycling stream. They are detrimental to ocean life (if they end up as litter) because they rapidly degrade plastic into microplastics.

Methodology

I relied heavily on sourcing information from scientific journals and articles to understand these polymers' scientific properties and use cases. Next, I used this information to fact-check the claims I found, mainly through manufacturers and distributors. See the Bibliography section for a complete list of articles and sources. I then assessed this raw information based on the most relevant questions (framework) EcoEnclose has identified in evaluating materials.

What is a Bioplastic?

Bioplastic is an umbrella term for plastics that are:

- Made from biologically-sourced materials

- Able to biodegrade at the end of life

- Or both.

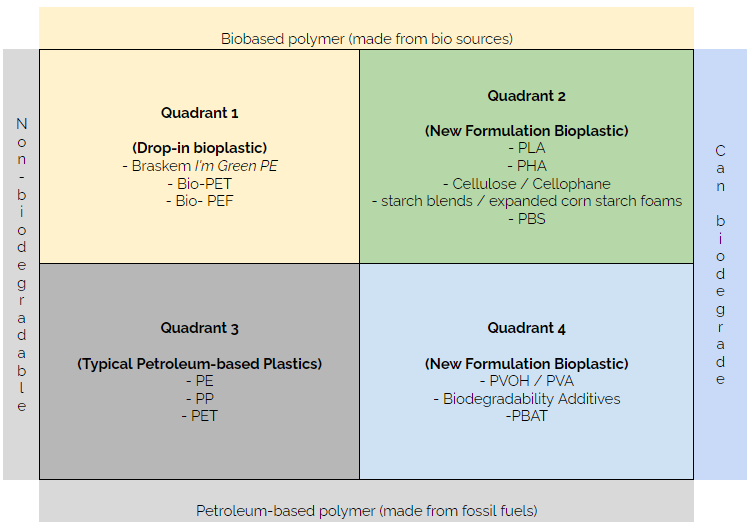

Bioplastics Formulations:

There are two main ways bioplastics on the market are designed: new or drop-in. They describe whether or not the bioplastic formulation is intended to be identical on a molecular level to a fossil-based plastic (drop-in) or represent an entirely new polymer structure altogether (new.)

- New formulation: a unique formulation that does not try to mimic a traditional petroleum-based plastic.

- Drop-in formulation: designed to mimic petroleum-based plastic counterparts have the same end-of-life characteristics as the petroleum-based alternatives they mimic.

Important Notes:

- "Can biodegrade" shows as binary (yes / no) in this chart, but this is a spectrum in reality. Some items (like PLA) require specific environmental conditions, others (like PVOH) require water, etc. The term “can biodegrade” does not mean it will biodegrade in every environment (i.e., marine/ocean, backyard composting, industrial composting, etc.)

- Biodegradable also does not equal compostable. A compostable material will break down in a composting process within a specific (short) amount of time, turn into compost, and leave no toxins behind. More info on this later.

- “Bio-based” does not necessarily mean that fossil fuels aren't still required in their production. An example: PLA+PBAT combination films, where PLA is primarily corn-based in the source material, but PBAT is petroleum-based.

These points are detailed further in this section and later matrices.

Quadrant 1: Bioplastic does not always mean the plastic is readily biodegradable - this is a common misconception. Bioplastics may be formed from bio-sources, like corn or sugarcane, but designed to be a replica of an existing plastic (like HDPE or LDPE) that’s currently petroleum-based, which would have the same end of life strategy - recycling (optimal) or landfill (sub-optimal). Square 1 includes bioplastics which are commonly referred to as drop-in bioplastics - meaning they could be dropped into an existing plastic production process and behave in the same way as petroleum-based plastic, including being recycled.

- Examples: Bio-PE, Bio-PET

- Rigid plastics that can’t use 100% recycled content and require some virgin plastics can use drop-in bioplastic instead of virgin, petroleum-based plastic.

- EcoEnclose’s recycled bubble mailers currently boast 50% recycled content, 10% of which is post-consumer waste. Though that’s an industry high for recycled content and PCR, it still requires 50% virgin poly content. We are pushing the supply chain to increase our recycled content levels. Suppose we learn this is truly technically infeasible. In that case, this could be an ideal application to use a drop-in bio-plastic (to replace the virgin plastic) if the bioplastic originated through net-neutral or even regenerative growing practices.

Quadrant 2: Bioplastics can also be bio-based in feedstock and biodegradable at end-of-life. This quadrant is the subsection that most people think of when considering bioplastics. It is the subsection of bioplastics we would encourage for applications that necessitate composting at the end of life, like food packaging. Ideally, these bioplastics come from net-neutral or net-positive feedstocks to grow and process on a large scale, like algae, mixed food waste, or agricultural residues. Currently, however (as is described at length in future sections), bioplastics in this quadrant are typically grown in ways that are pretty harmful to the planet.

- Examples: PLA, PHA, Cellophane, corn starch foams.

- Corn starch foam packing peanuts/molds, PLA biodegradable plastic mailers, cellophane clear food pouches.

Quadrant 3 [the only quadrant in the matrix that does not describe a type of bioplastic]: These are standard, petroleum-based plastics, which are not biodegradable at the end of their life. Both virgin plastics (0% recycled content) and recycled plastics fall into this square. Of course, at EcoEnclose, we put a high value on recycled plastics (specifically post-consumer waste or PCW recycled content) as a feedstock for our poly-based products. However, it would be misleading and irresponsible for us to believe or state that the use of recycled plastics does not require the use of virgin plastics too. To have recycled plastics (at least at this point) means that at one point, we needed virgin plastics to make the materials in the first place.

- Examples: LDPE, PE, PP, PET, r-PET (r- denoting recycled), r-PE, r-PP.

- Virgin or recycled rigid or thin-film plastics, like water bottles, poly mailers, rigid plastic containers.

- EcoEnclose’s poly mailers derive from r-LDPE and r-HDPE, and our clear flap and seal polybags derive from r-LDPE.

Quadrant 4: This is an exciting subset of bioplastics. These polymers derive from petroleum-based sources, not bio-based ones, yet they are technically biodegradable. Their benefit is the ability to break down in suitable environments but is best suited for specific functional requirements for use. People are often surprised to learn that some polymers biodegrade or dissolve much more readily than their bio-derived counterparts.

- Examples: PVOH/PVA (polyvinyl alcohol), PBAT (a chemical commonly used with PLA film to improve flexibility and speed up biodegradation).

- PVOH is commonly the plastic film that coats laundry and dishwasher detergent pouches and time-release medicines and pharmaceuticals.

Biodegradable versus Compostable

Biodegradable packaging is not equivalent to compostable packaging. Likewise, packaging can be certified as compostable and still not biodegrade in any natural land or marine environment.

According to the SPC, “‘Biodegradable’ is a general concept that refers to materials breaking down over unspecified amounts of time, and usually in unspecified environments…. we use the term “compostable” to describe packaging designed for composting as an end-of-life solution.“

On the other hand, compostable is a much more specific ability for materials to have to justify. According to the leading certifications for industrial compostability, ASTM D6400 (USA) and EN 13432, the following requirements must be met for a material to be considered compostable.

- Completely decomposes and disintegrates (at least 90%) in a composting setting. Within a set amount of time (usually 180 days or less.)

- 10% or less of solid material is left at the end of 6 months (180 days) in the form of valuable compost, water, or biomass.

- Minimal toxins or harmful residues are left behind.

Packaging deemed “compostable” does not mean that the material has to add nutrients or value to the resulting compost when it comes to packaging. However, compostable packaging must pass a specified minimum threshold of how much harmful residue is left behind.

Biodegradable asks: would this Poly Mailer degrade over time if it ended up as litter?

Compostable asks: would I use this Poly Mailer to fertilize my garden?

We believe that instead of asking questions such as “Is this packaging biodegradable?” or “Is this packaging compostable?” you should rather ask questions that help you determine how the packaging impacts your specific environmental concerns. For example:

- If left as litter, would this packaging biodegrade in a natural environment (land or ocean) in a reasonable amount of time without creating harmful micro nano-plastics?

- Would this packaging compost in a home compost bin? Would it add beneficial nutrients to the compost or bring in a trace amount of toxins?

When should Bioplastics be utilized? What is the role of bioplastics?

Historically, our stance has been that bioplastics have very little applicability in eCommerce packaging. Why? For many of the same reasons listed below from the Sustainable Packaging Coalition. eCommerce packaging (the packaging that stores and protects products shipped in the mail) is not designed to interact directly with food or naturally-biodegradable materials like organics, food, soil, medications, etc. Hence, we choose to solve for the most common and circular disposal method when designing our packaging - recyclability, not biodegradability.

However, bioplastics offer a unique benefit if we can produce them responsibly. Responsibly, in this case, means designing for ubiquitous biodegradability (versus highly conditional biodegradability) or recyclability.

Foodservice has already shown to be an incredibly promising application of bioplastics, a way to increase the percentage of diversion of food waste from landfills. Another application would be for materials that frequently result in litter on land or marine environments, like food or candy wrappers, straws, Ziploc or grocery bags, plastic pack rings, fishing nets or wires, etc.

|

Guidance from the Sustainable Packaging Coalition: From SPC's 2021 report "Understanding the Role of Compostable Packaging in North America" What is the value of compostable packaging?

Best Applications for Compostable Packaging:

What packaging applications should not be compostable?

SPC's Position Against Biodegradable Additives for Petroleum-Based Plastics |

We Prioritize Recycled Content As Our #1 Input Material

Materials Circularity is the number one tenet of our Sustainable Packaging Framework. This circularity requires making materials that can be recycled and, most importantly, sourcing materials made with recycled content. Doing so allows us to be suppliers and demanders of recycled content and participate in a closed-loop system.

Why are we so maniacal about recycled content?

First, items made with recycled content use less energy and resources than those made with virgin content. This fact is true for paper and plastic. According to the U.S. EPA, clean recycled plastic resin generation requires 71 trillion Btu less than the energy required to produce the equivalent tonnage of virgin PET and HDPE resin. The amount of energy saved by recycling PET and HDPE containers, including bottles, in 2008 was the equivalent of the annual energy use of 750,000 U.S. homes. The corresponding savings in greenhouse gas emissions were 2.1 million tons of CO 2 equivalents, comparable to taking 360,000 cars off the road. These calculations include the energy required to receive, sort, and transport waste into the raw materials stream.

Second, we have prioritized recycled material goods, specifically those with as much post-consumer waste as possible, so that we can be a market force for recycled material.

Post-industrial content refers to scraps created in a manufacturing facility. Post-industrial waste is fairly clean and pure and, therefore, relatively easy to work with and find markets for production. On the other hand, post-consumer content refers to recycling items that a consumer has already used. Recycled waste generated by your household, companies, restaurants, and so forth are all examples of post-consumer recycled waste.

An MRF is a materials recovery facility. This facility is where curbside recyclable material is received and sorted by a combination of awe-inspiring machines and even more awe-inspiring people. At the end of the MRF line, items are consolidated by commodity type (aluminum, corrugated cardboard, paper, plastic PET bottles, etc.). MRF’s “traders” then look for the price they can get for each commodity type on a given day. This process often means shipping pallets of aluminum or corrugated to a neighboring state. Recycling, therefore, only works if these “recycling traders” can make money, which only happens if there are eager buyers for these goods.

At the same time, it is crucial to understand that for some materials (such as paper), recycled content (especially post-consumer content) is inherently “weaker” than virgin material. With our current technologies, each subsequent stage in a material's life (i.e., after a new recycling round) leads to shorter and thinner fibers. Because of this, recycled material isn’t feasible today for all possible use cases. However, the impact of these shorter fibers is negligible in almost all eCommerce packaging scenarios.

Because eCommerce packaging is uniquely suited to utilize recycled content, we see an essential role for EcoEnclose to strengthen the demand for recycled inputs. Doing so would make the economics of recycling more appealing to waste management companies and incentivize manufacturers to go above and beyond to find ways to use post-consumer waste in their manufacturing.

By focusing on recycled (particularly post-consumer recycled content) and recyclable packaging, we stay true to our overall commitment to “cradle-to-cradle” thinking and make thoughtful decisions based on the material's entire lifecycle.

Why Bioplastics Seem To Be an Appealing Option At First

The product research compiled in this paper - mainly in the form of matrices and charts - will be the most immediately helpful information for readers to apply to decision-making, make sense of the materials on the market, and understand how they may relate to your needs.

However, I would encourage you to begin this process by first thinking deeply about the psychology around bioplastics and your reasons for considering them in your packaging strategy.

Consider both the surface structure and the deep structure of your rationale.

For example, we often hear “surface” questions:

- Does this plastic dissolve in water?

- Is this ASTM certified?

- Is this biodegradable?

- Can you add a biodegradable additive to this plastic, so it breaks down?

- Will this break down over time?

- Is this plant-based?

- Is this regenerative?

- Is this packaging compostable?

- Will this packaging biodegrade if my customers have backyard composting?

Let's examine these questions at a deeper level. Then, we can start to understand what companies are apprehensive about and trying to solve, such as:

- Will this packaging ever end up as litter (roadside or marine) somewhere? If so, will it harm marine or land life? If seen as a litter, will this negatively impact my appearance and credibility as a brand that cares about sustainability?

So why are bioplastics an appealing solution for brands in the first place? A few “deep” reasons come to mind.

- Environmental Reasons

- Eliminate the production of litter or ocean pollution

- The pursuit of zero waste

- A desire to have packaging come from non-petroleum-based sources

- Brand Reasons

- Novelty, industry-leading differentiation.

- Interest in an alignment with “natural” or “natural” ideals.

It’s relevant to dig deeper and name these deep structure reasons because the surface structure questions often do not give us insight into the whole picture. For example, biodegradable plastic may not mean this plastic has no chance of becoming marine plastic pollution. So if your most profound goal is to prevent plastic ocean pollution, start with this in mind.

Our Analysis

|

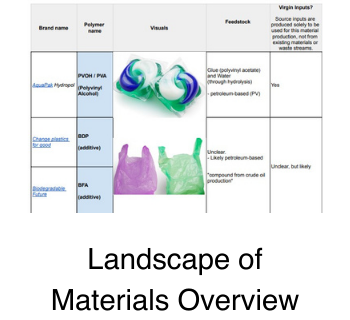

Matrix 1: Landscape of Materials Overview We highlight the market’s emerging and most common bioplastics. This chart provides an overview of each type of bioplastic, its typical applications and functions, feedstocks, and its designed disposal method. |

|

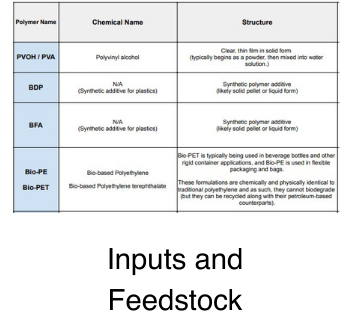

Matrix 2: Inputs and Feedstocks This matrix dives into the source inputs for these polymers. The chart showcases the source materials used to produce the polymer, its chemical makeup, and its creation process. This chart aims to provide you with a more holistic view of the impact of making each type of biopolymer. Recognize that the production of many biopolymer source feedstocks can be highly energy-intensive and polluting. |

|

Matrix 3: End of Life and Disposal Here, we detail what happens if a biopolymer is disposed of in various environments. Of course, it is easy to say that a specific biopolymer is “compostable” or “recyclable.” But to truly get at the “deep” questions that drive why brands are interested in bioplastics, it is critical to explore how materials will behave in all end-of-life situations. |

Tools and Resources

Terms and Definitions:

- Biodegradable: a more general concept that refers to materials breaking down over unspecified amounts of time, and usually in unknown environments

- Compostable: a concept that relates to materials breaking down over six months or less and not exceeding a specific level of toxicity or metals left behind (that may negatively affect the surrounding compost or microbial environment.)

- New formulation: a unique formulation (and does not try to mimic a traditional petroleum-based plastic).

- Drop-in formulation: designed to mimic petroleum-based plastic counterparts have the same end-of-life characteristics as the petroleum-based alternatives they mimic.

- Aerobic decomposition: decomposition of organic material in an oxygen-rich environment.

- Anaerobic decomposition: decomposition of organic material in a low-oxygen environment.

- Bioplastic: an umbrella term for plastics that are:

- bio-based

- biodegradable

- Or both

- Polyolefins: a name for the category of plastics including PE, PS, PP

- Monomer: a molecule of any of a class of compounds, primarily organic, that can react with other molecules to form huge molecules or polymers.

- Polymer: a chain of monomers joined together in a chemical process/reaction

- Biopolymer: a subset of polymers made by or from living organisms, produced through biological enzymatic processes

- Common feedstock examples: sugars, cellulose, starch polysaccharides (multiple sugar molecules- monosaccharides- linked in a chain structure.)

- Plasticizers: compounds that increase the plasticity of material and are often involved in the production of plastic products/packaging, epoxy resins (coating cans for food and beverage), water pipe lining, thermal printing paper, implanted medical devices, and in the production of CDs and DVDs, mobile phones, plastic food containers, eyeglass lenses, drinking bottles, food packaging, dental sealants, among many others (Source)

Mythbusting & The Bigger Questions

Carbon Footprint of Packaging

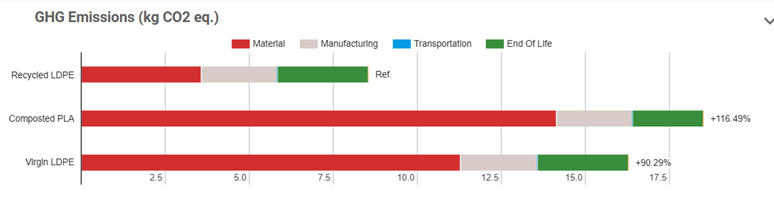

Myth: Bioplastics have a smaller carbon footprint

In Reality: Recycled plastics almost always have a lower carbon footprint than bioplastic equivalents made with virgin materials.

(Source: Trayak Packaging LCA Software) also referenced here.

When assessing the carbon footprint of packaging materials, the bulk of the footprint typically comes from the beginning of the product's life. These factors are typically:

- Source inputs/feedstocks - how they are generated.

- Source inputs/feedstock - their eutrophication impact (from fertilizers/agricultural additives.)

- The production process - how much energy is required to produce the product.

- The source of energy used for production - renewable vs. nonrenewable.

- The transportation footprint of inputs and the product - how far do components have to travel to be produced and sold? What kind of transportation is used?

- How often can the product be reused and kept from being disposed of?

Bioplastics like PLA require seeding, growing, and cultivating a crop-based feedstock (corn), then production processes to create the polymers themselves. Only then can manufacturing into polymer chains for packaging use happen. Compared to using a preexisting feedstock (recycled plastics), more innate energy is required to produce the equivalent amount of polymer from a crop.

Given that the input materials, production processes, and use of material typically make up 50% or more of the overall carbon footprint of packaging material, we’ve chosen to focus on these factors when considering the overall life cycle and carbon footprint of bioplastics.

Biodegradability Additives: Making Sense of Plastics in Landfills

Myth: Plastics should biodegrade instead of sticking around for thousands of years if most are going to the landfill anyway.

In Reality: Plastics that biodegrade quickly have a larger carbon footprint than those that biodegrade slowly. Therefore, materials meant for (or likely to be sent to) the landfill should not be biodegradable.

We do not recommend the use of biodegradable additives for eCommerce packaging. They can be confusing for consumers to know to correctly dispose of them, lead to more carbon emissions in the landfill, and contribute to greenwashing.

Landfills are, by nature, an entirely separate ecosystem from their surrounding environment - they do not have the same biology, microorganisms, or chemistry that a compost pile does. They are anaerobic (low in oxygen content). This reality means that as organic products break down without oxygen, they typically result in semi-solid sludge and methane-air emissions. In contrast, organic products like food that biodegrade in an aerobic (oxygen-rich) environment - like a windrow compost pile - can become beneficial biomass and naturally creates carbon dioxide as an emission.

Because methane being produced in high, consistent volumes by decomposing trash in the capped environment of a landfill is unsafe and unstable by nature, the vast majority of landfills are equipped with wells that release these emissions into the atmosphere. These are the giant metal poles that sit atop a landfill. In reality, they are many meters long and drilled into the depths of the interior of the landfill. They have small holes throughout their length to allow gas to permeate through and escape up the pole to a lower pressure environment - the atmosphere.

When we consider carbon footprint and climate change potential, methane is a much more potent and dangerous greenhouse gas than carbon dioxide is. Methane captures and absorbs about 25 times more heat than carbon dioxide, making one methane molecule as heat-trapping as 25 molecules of CO2. Therefore, we must reduce these greenhouse gasses with high heat-trapping potential as much as possible. Landfills are currently the third-largest source of methane emissions in the United States, making them a “super-emitter.”

MSW (municipal solid waste) landfills of a specific size must report their emissions (of methane, nitrogen, and more hazardous chemicals like VOCs) to the EPA or the designated state environmental agency. However, reporting, by itself, does not mean that the emissions themselves are reduced. Once landfills exceed a threshold of methane emissions, they must install gas collection systems or reduce these emissions in another way. Commonly, this other way is through “flaring” the methane that escapes - lighting it on fire as it leaves the emitting pipes. Flaring the methane effectively oxidizes the CH4 (methane) particle into CO2 particles. Better, because methane particles are broken up, but not great since CO2 particles are still emitted into the atmosphere.

While it’s possible to install equipment in landfills that capture this gas, clean it, and sell it as readily-usable natural gas fuel, this equipment is currently uncommon. This exciting technology is commonly called methane-to-energy. While we are hopeful that these systems continue to multiply across the country, we’re aware that they are currently used in less than 20% of landfills and are not legally required to be adopted by landfill operations. The EPA “tracks more than 2,600 municipal solid waste landfills. About 500 collect methane for energy production.”

Landfills separate materials from the outside environment. For this reason, nothing that biodegrades should find its way into a landfill. We sincerely want to reduce the linear model of take-make-waste that is the primary method for most single-use plastics and leads to their disposal in a landfill (or, at worst, ocean pollution.) We also recognize that a landfill is perhaps the best place for plastics that we cannot recycle. Their chemical structure remains intact and separate from the environment, and they do not biodegrade and release methane in less than hundreds or thousands of years.

Consumer Access to Composting in the United States

Myth: Compostable polybags are a better alternative than (recycled) plastic polybags.

In Reality: Most Americans do not have access to composting streams, making it unlikely that most of these polybags shipped will be composted. Instead, they’ll likely go to the landfill (and contribute to methane emissions) or be incorrectly recycled (adding to recycling contamination.) Unfortunately, even if consumers have access to industrial composting, few composters want or use the bioplastic eCommerce packaging.

Municipal curbside composting is still surprisingly limited across the largest cities in the USA. Additionally, most compost providers do not accept or prefer bioplastic wastes. Though compostable bioplastics can be an exciting option for brands, the reality of how consumers will dispose of those materials is less clear.

The SPC states that, as of 2020, “at least 11% of the US population has access to composting programs that accept some form of compostable packaging in addition to food waste.” Our most recent review of the composters in the 20 most populated cities of the United States, and their ideal inputs, tells a similar story: the vast majority of municipal and independent composting services for households do not want compostable bioplastics.

Access and practicality of sending bioplastics to an industrial compost collection stream are two major reasons we do not utilize these materials in our applications.

The Role of Water Treatment Systems in Packaging Disposal

Myth: Dissolvable plastics are automatically biodegradable plastics and the most accessible form of disposal. Everyone has a kitchen sink!

In Reality: Dissolvable plastics disappear down the sink, but that may not be good. Wastewater systems aren’t equipped to treat novel materials proactively and should not be considered an additional consumer “waste stream.” Protecting our water is critically important.

We must understand and recognize the limits of the wastewater treatment systems across our country. For example, suppose dissolvable plastics begin to increase in number. In that case, this is the system that will be relied on for remediation of these water-soluble materials (and the environmental regulatory bodies and policies that regulate them.)

Anything flushed down the sink, the tub, the toilet, or the gutter will eventually make its way to a wastewater treatment plant. The processes used in wastewater treatment have remained mostly the same over the last fifty years, while the types of materials introduced into their systems have changed rapidly. The Clean Water Act of 1972 regulates WWTPs. Across the country, they are in constant need of repair and improvement. As a result, Wastewater Infrastructure scored a D+ from the Infrastructure Report Card of America. WWTPs are responsible for cleaning the municipal water and sewer effluent before releasing it eventually into surface waters.

I bet you didn’t think you’d be getting a lesson on wastewater screening when you opened this resource, huh? But, trust me, it’s relevant.

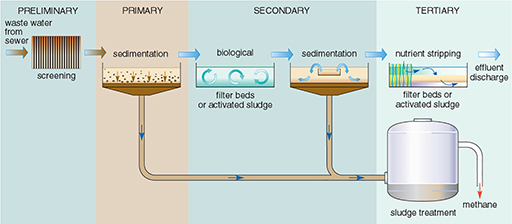

Source: The Open University, Understanding water quality, Figure 18

As sludge from the combination of water effluent sources makes its way to a wastewater treatment plant, it goes through some basic filtration steps:

- Preliminary Treatment:

- Screening, by giant screens and sieves. These screens catch and remove the bulk of solids from the water - like paper and fiber, wood, litter, food, and organics. These materials go to another process (sludge treatment) where the solid organics are dried out and often landfilled. In some cases, the organics can be used again as land-cover or soil amendments assuming they do not contain toxins or metals, but this is less common than landfilling or incinerating them.

- Primary Treatment:

- The effluent remaining from the first screening methods then goes through several processes to settle out silt, grit, sand, and suspended organics/solids (molecules of food or organic polymers.) These processes use basic physical laws like gravity, aeration, and more screens (with smaller and smaller holes) to weed out the rest of the contaminants.

- Grit Chambers / Clarifiers: slow down the water and allow it to sit still so that the heavier particles in the water can sink to the bottom and be screened out. Those particles head to sludge treatment.

- Secondary Treatment:

- Biological / Activated Sludge: this process relies on the superpower of microbes and bacteria, which are added to the remaining effluent, churned up to add oxygen by large paddles, and allowed to sit for 10+ hours. The microbes eat the organic materials, breaking them down and creating another waste stream of sludge that settles at the bottom of the tanks, and is sent to sludge treatment.

- Aeration: the remaining effluent is exposed to oxygen, bubbling up from the bottom of the tanks, where the oxygen molecules can chemically interact with remaining solids, bringing a portion of them bobbing to the surface of the water as foam. This foam and other suspended solids are screened off the top and sent to sludge treatment.

- Activated Sludge: one more time, for good measure.

- Disinfection: chemicals like chlorine are added to the finished product to kill several pathogens and potentially harmful remaining molecules.

- Tertiary Treatment:

- WWT plants require tertiary treatment if they release pollutants like toxic chemicals, metals, or high volumes of nitrogen or phosphorous (which cause eutrophication and severe damage to aquatic environments downstream). If they do not release these pollutants, this is a more expensive and thus less common final step in treatment.

- This step can include treatments like UV radiation for disinfection, nutrient stripping, or nano-filter membranes and screens.

Once through treatment, the remaining effluent leaves the treatment plant and enters the environment. The Clean Water Act regulates WWTPs, so consistent testing and reporting to the EPA and state environmental agencies are required. This testing ensures that plants don’t pollute more of any given water contaminant into the environment than legally allowed.

Wastewater regulation and treatment have two critical takeaways.

The first is that the only pollutants regulated by law and included in the CWA or EPA regulations have already been proven dangerous or harmful to humans and the environment. This list of contaminants is slow to be updated, reviewed, and regulated.

More explicitly: wastewater treatment has been designed around the materials in the sewers of the late twentieth century. It is not proactively updated as new water-soluble materials come on the market.

The second is that WWTPs have a unique loophole for their “discharge” regulations or the number of pollutants that facilities can discharge to the environment after treatment. Regular monitoring and testing are required to ensure the levels of pollutants are within the scope required by law. However, this testing is not required in the cases of stormwater overflows. Sewage systems are responsible for taking and treating human-produced water waste and the water that flows in from stormwater drains and gutters across a municipality. In the cases of flash floods, heavy rains, or hurricanes, when the sheer volume of water entering the sewer system exceeds the limits of what a WWTP is designed to treat, the regulation requirements fall away. There is no testing required and no way to ensure that the water through this system is free of the typically regulated contaminants.

In a world where our weather is becoming more and more erratic, storms are stronger, and less ground is permeable for water (i.e., grass and soil replaced by pavement), these surges become more likely and more common.

Cautionary Tales, Discernment, and our Responsibility to Water.

History has taught us that, when it comes to water, we often react and legislate too late after significant harm has already been done to our waterways and local communities that rely on that water. Because of this, as we evaluate bioplastics, we are particularly cautious about any bioplastic that is designed to dissolve in water.

In the last several years, we have seen a growth in an interesting trend in the sustainable packaging zeitgeist: dissolvable plastics and packaging. Commonly, PVOH/PVA is produced into clear thin films to rival a typical polybag, and cornstarch is expanded into foams to be used as a void fill or protective packaging option.

Water dissolution is the preferred end-of-life method for water-soluble/dissolvable plastics and biopolymers, specifically PVOH/PVA and Cornstarch foams. They are often encouraged to be dissolved in water and down your kitchen sink.

Generally, we tend to remember and heed the lessons learned from famed tales of the environmental externalities that have wreaked havoc on human and animal health. These externalities include DDT, microplastic beads, and PFOA/PFAS. We share them here to illustrate the gravity and reality of these chemicals and their stories’ value in our current discernment.

|

DDT DDT was a chemical popularized in the 1940s, meant to be used as an all-purpose and state-of-the-art pesticide. We distributed it widely over the farmlands that had grown and strained under pressure to support a country recovering from war and economic decline. “Distributed widely,” meaning released by cars and planes in giant plumes of powder across farmland, streets, and neighborhoods and used in households for pest control. It was everywhere. Cut to two decades later. To the scientific community, it has become growingly certain that the impact of DDT on natural environments is harmful. Rachel Carson’s seminal book “Silent Spring” was published in 1962 and detailed its impacts on harming the genetics and health of birds and insects; she explored a world without the songs of birds every year. Birds of all types suffered, but one of the most notable was the sudden decline in populations of Bald Eagles. The chemical impacted the thickness of their eggshells, endangering and rapidly reducing the number of chicks that survived. Carson’s book became the first major example of literature impacting the choices and demands of Americans’ interaction with the environment. Importantly - DDT was not immediately banned by the companies who produced it, nor was the subject of a drop in sales through mass protesting. Instead, it took ten years for the chemical to be legally banned and its production and use to be controlled. For eight of those years, the EPA was not yet in existence. |

|

Microplastics Microplastic beads dominated scrubbing beauty products - like face and body washes - from the early 2000s until 2012. The research concluded that we had found microplastic beads in the open waters of Lake Ontario, one of the Great Lakes of North America. These findings began an incredibly swift public outcry, education campaign, and urge to protest and prevent using products containing these plastics. Microplastic beads were subsequently banned in 2015 and eliminated by 2018. However, this was just the beginning of our public and corporate conversations about marine plastic pollution in the form of microplastics that degrade and anatomize from tons of plastic waste (rigid, thin-film, micro, textile) that make its way to waterways each year. Most water and wastewater treatment plants do not have the technology or capability to screen out and “treat” microplastics in water the way they do for dozens of other contaminants. Since their molecular size is so small, they can move past most screens and sieves and make their way to the environment and into the bodies of larger and larger animals. This phenomenon is called bioaccumulation: toxins increase in quantity as they move from prey to predator in a food chain, making the apex of the food chain the home of high levels of toxins or contaminants. In fact, as of March 24th, 2022 (two days before writing this sentence), a study found the presence of microplastics in a majority of human blood - 17 out of 22 test subjects. |

|

Teflon If you have read the excellent New York Times article The Lawyer Who Became DuPont’s Worst Nightmare (seriously, if you haven’t read it - read it) or seen the 2020 movie Dark Waters, you are familiar with the acronyms PFOA or PFAS. If not, these chemicals result from unique chemical technologies - most commonly, Teflon. Produced by 3M in 1947, then adopted by several chemical giants, and used ubiquitously by producers of household items like nonstick frying pans, PFOA/PFAS was proprietary and an incredibly profitable chemical. A West Virginia farmer whose cattle were mysteriously ill and dying asked for help from a friend-of-a-friend, big-shot, corporate environmental lawyer in 1998. His land was downstream from an industrial landfill, owned and operated by DuPont, which held and managed the nearby plant’s toxic waste. The investigation into the dangers of PFOA began - but only by one lawyer, Rob Billot, and only because he felt obliged to help this farmer who had been turned away by everyone else in his quest for help. From the chemical production and its use in Teflon products, PFOA/PFAS molecules became water-bound and found their way into water systems, environments, and drinking water. It eluded existing wastewater treatment technologies and was invisible in its volumes and impacts to regulators and operators. It found its way into natural environments and drinking water systems around the country. After ongoing work and legal processes, in 2011, studies into PFOA found it was an endocrine-disrupting chemical and had probable links to a wide range of cancers in humans and animals. As a result, in 2020, the EPA banned its use in the USA after 70 years of use. |

There is a common thread between these stories. It links back to arguably the most important reality of environmental regulation: chemicals used in industry are not regulated until they have been proven to be harmful. It’s “innocent until proven guilty” for synthetic materials.

This article detailing the story of PFOAs so beautifully summarizes: “‘corporations could rely upon the public misperception that if a chemical was dangerous, it was regulated.’ Under the 1976 Toxic Substances Control Act, the E.P.A. can test chemicals only when it has been provided evidence of harm. This arrangement, which largely allows chemical companies to regulate themselves, is the reason that the E.P.A. has restricted only five chemicals, out of tens of thousands on the market, in the last 40 years.”

Our responsibility to water? Prudence. Water is arguably our most vital and sparse natural resource. Less than 2% of all water on Earth is freshwater, which all living things solely rely on for life. Understanding the precious nature of this resource and the realities of water treatment technologies and policy, we must use extreme diligence to discern the materials we release into it.

PVOH Takeaways

The vast majority of research currently available about PVOH/PVA - Polyvinyl Alcohol - suggests that it is safe for human and aquatic life in controlled environments (liquid solutions) of <5% concentration. This research does not mean that we are choosing not to still deeply consider introducing and increasing this material in our water systems. PVOH is used in many medical and saponic products as a clear coating for medication or cleaners. If you use laundry or dishwasher pods, you interact with PVOH - it’s the clear coating that keeps the soap in place and dissolves in the process. These approaches make a lot of sense given the use case: a product that interacts with water, anyway, in a system that would receive and treat that waste or dirt being removed in the first place.

We don’t think a massive use of PVOH as the input source for packaging films is the best use case for this polymer. First, it requires a much higher amount of PVOH source materials (polyvinyl acetate, aka glue) to make a polybag than a detergent pod. Since this is a petroleum-based product, the feedstock is not ideal. This same volume of PVOH needed for production is then making its way into water treatment systems. Thus far, scientific consideration of PVOH shows it is likely a relatively benign chemical when used in moderation. This article, published in the International Journal of Environmental Research and Public Health, takes a close look at the impact of its use on water in the USA. Its conclusion?

|

“We observed that PVA has low degradation rates within WWTPs [wastewater treatment plants]; thus, its hydrophilicity and massive production numbers make it a cause for concern as a pollutant in the natural environment. Very little research exists that aims to monitor the biodegradability of PVA in the natural environment. This presents a challenge in determining its role or impact as a pollutant.” |

The environmental regulation of most chemicals used and created by non-FDA regulated industries are, by nature, reactionary. Given this, when it comes to novel materials we are introducing in large quantities into our water, we should be determining their necessity upfront. Instead of qualifying what materials we put down the drain by asking “why not?”, we should instead be asking “why should we?”

Our [Current] Conclusion: When and How to Use Bioplastic Packaging

These questions help create a larger framework for assessing materials. They are the questions that are most important to our company ethos. You could extrapolate and call these our corporate sustainability values.

At EcoEnclose, we use a Sustainable Packaging Framework to allow us to do the same fundamental assessment for packaging materials and products that come on the market. That way, we don’t have to research all of the ins and outs of each product to determine whether we support it, use it ourselves, or offer it to our customers. Instead, we see how it aligns with our values and scores on our framework and go from there.

Inputs:

|

Functionality:

|

End of Life:

|

An Ideal Bioplastic

We recognize that there is no bioplastic currently on the market that meets our vision for circularity (able to be readily recycled back into itself) and our standards for sustainable input materials (regenerative crops or feedstocks, existing waste streams, agricultural residues.)

So, what would our ideal eCommerce bioplastic be? Here are the things we look for when it comes to bioplastics.

| Inputs | Function | End of Life |

|

|

|

With this framework in mind, as of today, we find that recycled content is still very much superior to any bioplastic material available. However, as EcoEnclose explores use cases where composting is preferred (i.e., food/organics) or where the strength of a virgin plastic polymer is genuinely required, we may find ourselves turning to bioplastic solutions that meet the above framework.

We recognize that the above research is helpful in myth-busting and making sense of the biopolymers on the market. However, it does not immediately help answer some practical questions about achieving your sustainable packaging goals. We have existing resources that may help you in these journeys available on our website.

Transitioning from Poly to Paper Packaging (Published February 2024)

Guide to Sustainable Inner Packaging (Updated October 2022)

Moving your Fulfillment Center to a Sustainable Packaging Strategy (Published January 2022)

As always, EcoEnclose welcomes questions and interests in all things sustainable packaging. If you need advice, ideas, or support, please reach out to us. Our team will be happy to work with you.

888-445-6575

hello@ecoenclose.com

www.ecoenclose.com

Recommendations for Ongoing Learning

Certifications and Standards

-

Composting Manufacturing Alliance (CMA) (North America)

-

Field Testing for products meant for industrial compost.

-

Works with composters across North America to assess how well products will break down in modern, large-scale compost manufacturing technologies.

-

CMA is the compostability certification for food packaging and all other meant-for-compost materials. This certification is the one EcoEnclose would pursue over any other. There is no North American certification for Home Compostability and no corresponding ASTM stand at this publication.

-

ASTM D6400: for compostable bioplastics (North America)

-

Industrial Composting applications

-

ASTM: D6868: for fibrous packaging with compostable bioplastic additives or coatings.

-

Industrial Composting applications.

-

Most prevalent method for scientific substantiation for the percentage of material that is bio-based (bio-based content). Determines how much carbon of the material has recently been in the atmosphere versus how much has been in the ground (fossil-based.)

-

BPI (Biodegradable Products Institute)(North America)

-

A third-party verifier of ASTM standards for compostable products in North America.

-

“Requirements for packaging recoverable through composting and biodegradation”

-

“Test scheme and evaluation criteria for the final acceptance of packaging”

-

“This is a harmonized European standard linked to the European Directive on Packaging and Packaging Waste (94/62/EC). It allows for the presumption of conformity with essential requirements of the Directive. It has been translated and implemented in all the European Member States.”

-

“Evaluation of compostability”

-

“Test scheme and specifications”

-

“It broadens the scope of plastics when used in non-packaging applications. The EN 13432 applies when plastics are used for packaging.”

-

Industrial Compostability applications

-

Complies with EN 13432.

-

Home Compostability applications, assuming your home compost environment meets the requirements outlined by TUV.

-

OK Compost HOME is not based on a standard.

-

It does not explicitly refer to a specific standard but details all the technical requirements that a product must meet to obtain the certification.

-

Australasian Bioplastics Australia (ABA) (Australia) AS 4736-2006

-

Industrially Compostable:

-

Australasian Bioplastics Australia (ABA) (Australia) AS 5810-2010

-

Home compostable

Industry Thought Leadership and Guidance

-

Ellen MacArthur Foundation

-

US Plastics Pact

-

Problematic and Unnecessary Materials List and Decision Tree

-

UNEP (United Nations Environment Programme)

-

Columbia University: Columbia Climate School

Additional EcoEnclose Resources

-

Bioplastics Are Not a Silver Bullet Sustainability Solution: Whitepaper 2018

-

EcoEnclose Guide: Transitioning from Plastic to Paper Packaging

Bibliography and Sources

-

BFA

-

BDP

-

Bio-PE/Bio-PET - Braskem I’m Green

-

PEF

-

PBS

-

https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/succinic-acid

-

https://www.roquette.com/industries/performance-materials/polyesters-pbs

-

PVOH / PVA

-

https://onlinelibrary.wiley.com/doi/10.1002/14356007.a21_743

-

https://www.degruyter.com/document/doi/10.1515/tsd-2020-2326/html

-

https://www.sciencedirect.com/science/article/abs/pii/S0269749120360528

-

PHA

-

https://cen.acs.org/business/biobased-chemicals/PHA-biopolymer-whose-time-finally/97/i35

-

https://news.climate.columbia.edu/2017/12/13/the-truth-about-bioplastics/

-

PFOA/PFAS

-

Wastewater Treatment

-

https://www.sciencedirect.com/science/article/pii/S2667010021002432#bib0007

-

https://www.sciencedirect.com/science/article/abs/pii/S0043135416300021

-

Composting Access

-

SPC Compostable Plastics and Biodegradability Additives

-

Plasticizers

-

Landfill Gas

-

Landfill Gas Recovery

-

Microplastics