Paper versus Plastic (and Bioplastic)

Table of Contents

- How EcoEnclose Evaluates Packaging Materials

- Renewable and Sustainably Grown Material

- Ability to Use Recycled Content

- Energy, Resources, and Pollution From Manufacturing

- Energy, Resources, and Pollution From Shipping and Storage

- End-Of-Life, Ability, and the Likelihood of Being Recycled or Disposed of Properly

- Other Challenges of Plastic

- What Does This Mean for Packaging?

- Shop Recycled, Recyclable, Eco-Friendly Packaging

We hear it repeatedly from the great businesses we work with, all of whom have a strong eco commitment -- “We are banishing plastic from our business and our lives.” And we get it. The very thought of a plastic bag - made with fossil fuels, used just once, then ending up in the Great Pacific Garbage patch, decomposing over 1000 years, getting stuck in the bellies of seagulls and fish - is more than enough to make you swear plastic off forever. We’re with you and deeply respect your passion and commitment!

But is plastic genuinely evil? Is paper more eco-friendly than plastic? Could bioplastic be the answer to some of this?

Surprisingly, these questions do not have clear and easy answers. A proper overarching response would be:

All materials have environmental downsides - no material is perfect or a silver bullet.

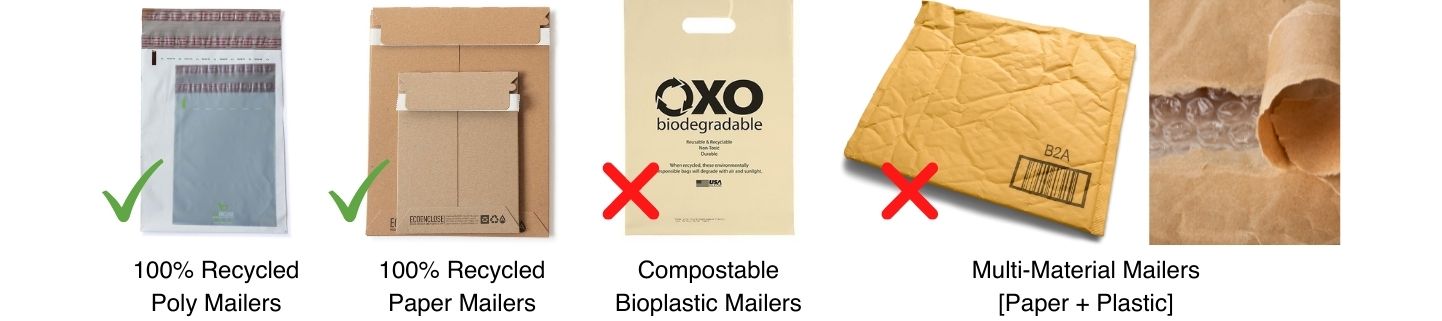

However, regardless of what material you choose, we strongly encourage you to opt for 100% recycled content with the highest post-consumer waste possible. If your goal is to minimize your carbon footprint or need a waterproof material, opt for thin, 100% recycled plastic packaging. If your goal is to maximize circularity and ensure your packaging does not contribute to ocean plastic pollution, opt for 100% recycled. We strongly recommend avoiding current compostable, bioplastic packaging options for eCommerce, given how ecologically damaging their source material and end of life is to the planet.

How We Evaluate Packaging Materials

The ultimate goal of sustainability is for humans to exist in ways that strengthen and regenerate the planet for all future generations. Learn more about our vision for circularity.

Sustainability is therefore not straightforward. For example, sustainability can’t just boil it down to end-of-life or where materials end up once consumed.

Instead, we consider the following 360-degree questions to get at more of a life cycle understanding of the footprint of different materials:

- Source materials: Can recycled content be used efficiently for these materials? Are the raw materials for that material renewable or nonrenewable?

- Manufacturing: What are the resource implications of manufacturing the raw material? How much energy is needed, water consumed, and pollution created through manufacturing? What are the energy and resource requirements for distributing and storing the raw materials?

- Use and end of life: What are the end-of-life options for the raw materials? How easily can they be recycled back into themselves?

The following chart provides a very high level (and admittedly oversimplified because of how complex these topics are) comparison of three common eCommerce packaging materials.

We have given each material an overarching rating of good, moderate, or poor to indicate how well each material typically embodies each criterion. The chart does not aim to provide a perfect number representing the carbon footprint of material because that is not feasible given the many factors that influence this. For example, each piece of paper has a different carbon footprint depending on what forest its raw materials came from, the paper mill where pulped, and how much recycled content went into it. Instead, the chart and this piece aim to help readers understand the dimensions by which to assess a material and packaging solution and the importance of going beyond just one dimension, such as end-of-life.

Bioplastic is a broad term encompassing many different materials with different source materials and end-of-life options. Here we mainly refer to PLA (and PLA blends), the most common input in bioplastic shipping solutions.

|

Plastic |

Paper |

Bioplastic |

||

|

Renewable, Sustainably Grown Material | Never made from renewable resources. | Can be sustainably grown, but irresponsible logging is disastrous. | Though corn is “renewable,” its production wreaks havoc on the planet. |

|

Ability to Use Recycled Content | Highly feasible but not yet common. | Highly feasible and very common. | Not currently feasible or common. |

|

Energy, Resources and Pollution from Manufacturing | Relatively efficient to produce, ship and store. | Resource-intensive to manufacture, ship, and store. |

Converting corn into PLA bioplastic is moderately energy-intensive. |

|

End-Of-Life, Ability, and the Likelihood of Being Properly Disposed | Readily recyclable, but film must go in a single stream bin. Therefore, it does not damage the environment in landfills. | Readily recyclable curbside and recycled at high rates. It does create emissions in landfills. | Unrecyclable, causes damage in landfills. Compostable, but not often composted, and does not increase compost quality. |

Read on to learn how we have classified materials as such and better understand the facts, myths, and nuances about these materials.

Learn More: Comparing Composable Mailers and Recyclable Mailers

Renewable and Sustainably Grown Material

Plastic - Poor

Plastic is made directly from fossil fuels, which are nonrenewable resources. Estimates state that 4% of the world’s oil production is used as a feedstock to make plastics.

It is essential to understand that many plastics, LDPE #4 or “plastic bags” in particular, are made from ethane, a byproduct of natural gas production. We would typically burn off ethane to lower the BTU value of the gas so that it doesn’t burn too hot when used as fuel in our homes and businesses. Plastic production in this way actually “captures” this ethane instead of having it burned and released into the atmosphere. This process is not to say that virgin plastic is impressive, and we should all celebrate it as a green innovation! However, as long as we heat our homes and run our stoves with some degree of nonrenewable resources, such as natural gas, there are some efficiencies in extracting the raw materials associated with plastic.

We have categorized plastic as “poor” when it comes to renewable, sustainably grown material given that plastic is make directly from a nonrenewable resource.

Paper - Moderate

Paper is typically made from trees, though occasionally (thus far, especially in the U.S.) from straw or hemp. Trees are a renewable resource, which is “good.” However, renewable isn’t a great thing if the paper comes from global deforestation - one of the significant contributors to climate change and loss of wildlife habitat. Thirteen million hectares of forest disappear every year (although afforestation adds another eight back). The World Resources Institute (WRI) estimates that only about 22% of the world’s old-growth forests remain intact.

Thankfully, paper manufactured in the U.S. is typically not to blame for most of this. WRI estimates that agricultural expansion (i.e., the need to produce more and more palm oil) accounts for probably 80% or more of tropical deforestation. Most paper in the world comes from “production forests” - fast-growing wood growing operations with 5-10 years of harvesting cycles. At best, these production forests have a positive impact, as seedlings and growing trees capture carbon more effectively than the agricultural land these operations may have replaced. At a minimum, this production approach means we can create wood products without logging in old-growth forests. Certifications such as Forest Stewardship Council help users seek out virgin paper made from trees that have been grown in positive ways.

We have categorized paper as “moderate” for renewable, sustainably grown material. While wood for paper can be a net positive renewable resource, the logging and paper industry has not yet reached a point where net positive, certified tree forestry and logging is the standard.

Bioplastic - Poor

Bioplastics are plastics made from plants, including corn, sugar cane, and algae.

Cargill’s NatureWorks is the largest producer of bioplastics and produces its material from corn in the U.S. Corn kernels are processed and milled to extract the dextrose (a type of sugar) from their starch. Dextrose is fermented into lactic acid and converted into lactide. The lactide is “polymerized” to make long-chain polylactide acid (PLA) molecules. PLA looks and behaves like polyethylene and polypropylene and is now widely used for food containers. Note that though there is a lot of talk as of late about bioplastics, the concept is not necessarily a new one. The world’s first plastics were plant-based. “Cellophane,” once commonly used for food packaging until petrochemical plastics rose in popularity, is made from cellulose, the structural component of plants.

Okay, so U.S. bioplastics are made from fast-growing corn - so it must be a great, renewable resource, right? Not so fast. Corn is an environmentally terrible way to make plastic.

Corn for bioplastics is grown on land that farmers could use to grow food. In fact, in 2014, almost a quarter of U.S. grain production was for biofuels and bioplastics production. Taking agricultural land out of production could cause a significant rise in food prices that would hit the poorest people hardest worldwide. Additionally, growing crops to make bioplastics comes with the usual environmental impacts of intensive agriculture, including greenhouse emissions from the petroleum needed to fuel farm machinery and water pollution caused by runoff from land where fertilizers are used in industrial quantities. In some cases, these indirect impacts from “growing” bioplastics are more significant than if we made plastics from petroleum in the first place.

Further, some bioplastics, such as NatureWorks PLA, are typically made from genetically modified corn. Scientists have designed genetically modified corn to endure an onslaught of chemical pesticides without destroying the crop. Unfortunately, genetically modified corn production fields often generate more chemical runoff and health hazards for workers and their communities than non-GMO corn.

We have categorized bioplastic as “poor” for renewable, sustainably grown material because corn is the primary source material for plastic today, and corn is a poor replacement for fossil fuels. We follow and research innovations related to bioplastics and look forward to an era when less resource-intensive inputs (such as algae) that do not displace agricultural land become the critical drivers of bioplastics.

Ability to Use Recycled Content

Plastic - Moderate

Historically, we did not turn plastics back into original materials. Now, we can recycle almost all plastics into something. For example, plastic bottles become materials for park benches, Styrofoam becomes picture frames, and plastic bags become composite lumber. However, innovations make it more common for plastic to be recycled back into its original use. For example, CarbonLITE Industries recycles more than 2 billion PET bottles into food-grade post-consumer PET and is one of the world’s largest producers of food-grade recycled PET. EcoEnclose’s recycled poly mailers (made with LDPE #4 plastic) derive from film and plastic bags (also LDPE #4). Recycling plastic from its original use back into itself (versus downcycling plastic) is a newer phenomenon because the process is complex and requires investment and innovation. Historically, recycling rates for plastic have been low, meaning that a steady supply of recycled plastic was not available.

When recycled, plastic is melted down, formed into pellets, and used again to create raw materials like film and mailers through heat-based molding or blowing. However, because recycled plastic has contamination and ink, the recycled plastic feedstock is lower quality and less consistent than virgin plastic pellets. In addition, the unstable resin can stop and break machines because its melting point or reaction to heat is too unpredictable. This process can lead to wasted resources going into creating unusable goods. Therefore, manufacturers of recycled plastic material must find the right blend of virgin, post-consumer, and post-industrial plastic for their particular machines and end-use cases.

We have rated plastic as “moderate” in its use of recycled content because this is a feasible technology that is progressing rapidly. On the other hand, it is currently difficult for manufacturers to achieve high levels of recycled content and very high levels of post-consumer recycled content. The world of recycled plastics is evolving and advancing rapidly. The more consumers demand recycled content in their plastic; the more companies will work to meet this need.

Paper - Good

In contrast, paper is relatively easy to recycle back into paper. It is a non-synthetic material whose manufacturing process does not rely on chemical reactions. Therefore, it can be repulped and reasonably put back into the paper mill/manufacturing supply chain. It is also more forgiving of contaminations in the post-consumer waste stream. Making 90% and even 100% post-consumer recycled paper is much easier than making 100% post-consumer recycled plastic.

We have rated paper as “good” in using recycled content.

Bioplastic - Poor

Finally, to date, the world of bioplastics is almost entirely driven by virgin materials. We can put a minimal set of bioplastics back into the recycling stream, but they are treated as “traditional” plastic when they do.

We have rated bioplastic as “poor” in its use of recycled content because there is currently little investment in this space. If bioplastics become more common, we are hopeful that bioplastic manufacturers will invest in using recycled content, and recycling sorting facilities (MRFs) will be able to accept and sort bioplastics.

Energy, Resources, and Pollution From Manufacturing

Paper - Poor

Making paper from trees is dirty work. At a paper mill, trees are de-barked, cut into wood chips, and then fed into large pressure boilers called digesters. This process reduces the wood chippings to an oatmeal-like pulp, which when extracted from the digester is one part fiber to 200 parts water. The pulp is then deposited onto a high-speed mesh screen loop, removing most of the water content and leaving a thin layer of raw paper. This pulp is pressed and heated in a series of drying cylinders, removing any traces of moisture. Finally, the pulp is treated with a starch solution to seal the surface and avoid excessive ink absorption during printing. Unfortunately, 20% of toxic waste in the air in the U.S. is due to the pulp and paper industry. Wastewater pollution is a massive problem as manufacturing discharges contain pollutants such as lignin, chlorates, transition metals, nitrogen, and phosphorus. These are just a few toxins that should not be spreading into our rivers and oceans.

An excellent paper mill can positively impact the environment, for example, by taking in dirty water from a river and releasing clean water. A paper mill with a comprehensive water reuse system uses wind and solar energy, scrubs air emissions and water before release, offsets its carbon emissions, and obtains reputable certifications to prove these actions can drastically reduce its negative impact.

Boustead Consulting & Associates Ltd. compared traditional plastic grocery bags (also made with LDPE #4, similar to poly mailers) to paper bags. They found that manufacturing 1,000 paper bags requires 3.4 times more energy than traditional plastic, and manufacturing compostable plastic bags requires 2.7 times more energy than conventional plastic.

We have given paper a “poor” rating regarding energy, resource, and pollution from manufacturing given this research.

Plastic and Bioplastic - Moderate

Plastics manufacturing is energy-intensive, with 4% of the world’s oil production going into just plastic processing. However, plastic manufacturing requires less energy than paper and even bioplastic.

We have given both plastic and bioplastic a relative “moderate” rating for this criteria; however, studies (including both the one cited above and one conducted by the University of Pittsburgh) have shown that the manufacturing alone of bioplastics is more energy-intensive than traditional plastics.

Energy, Resources, and Pollution From Shipping and Storage

Paper (Poor) Plastic and Bioplastic (Good)

Distribution and storage of traditional and bio-based plastic types are typically more efficient than paper. Plastic is lighter and thinner.

For example, EcoEnclose stocks recycled poly mailers and recycled kraft mailers. While none of them is the same size, we have comparable ones, such as a 14.5 “x19” poly mailer and a 12.5 “x19” kraft mailer. The kraft mailer is slightly smaller than the poly mailer, but the poly outperforms the kraft in shipping efficiency.

A single poly mailer of this size weighs 0.8 oz versus the comparable kraft mailer, which weighs in at 2.2 oz. A case of 250 poly mailers is 768 cubic inches (16” x12” x4”), while a case of 200 kraft mailers is 2990 cubic inches (23” x13” x10”). A single 48” x48” pallet can hold 30,000 poly mailers versus just 4,800 kraft mailers.

Therefore, the significantly lighter and thinner poly bags are more energy-efficient to ship across the entire supply chain, including to your business. They also require significantly less energy and space to store than the equivalent number of paper-based mailers.

Thus, We have given paper a “poor” rating and plastic (both traditional and bioplastic) a “good” rating on energy, resource, and pollution of shipping and storage.

End-Of-Life, Ability, and the Likelihood of Being Recycled or Disposed of Properly

Plastic - Moderate

Plastic bags or poly mailers (#4 LDPE) can and should be recycled; however, this is not an easy process for consumers. Unfortunately, most single-stream, curbside recycling programs cannot accept LDPE #4. The facilities that sort single-stream recycling bins (MRFs) cannot handle flexible, shapeless plastic due to the limitations of their equipment. The bags get caught on these machines’ wheels and gears, causing costly shutdowns. To recycle plastic bags, most Americans must take them to a designated drop-off site located at most grocery stores and major retailers.

Plastic recycling rates, in general, are poor in the U.S. According to the EPA, only 9.5% of plastic material generated in the U.S. Municipal Solid Waste (MSW) stream was recycled in 2014. Estimates state only 3% of plastic bags are recycled. Additionally, while we CAN recycle plastic bags back into plastic bags, this does not always happen. Instead, they often come back as composite materials, such as Trex. While this is better than sending plastic to landfills, it is not as beneficial to the environment as materials that are recycled “back into themselves.” The positive trends here are that most Americans have some access to plastic bag and poly mailer recycling and that recycling rates are rising. We hope trends towards increased recycling rates of plastic will happen when (1) MRFs adopt equipment that can sort plastic bags in single-stream recycling and (2) there is increased demand for recycled plastic, specifically #4 LDPE plastic.

So what happens if traditional plastic does not end up in the recycling stream? For example, plastic grocery bags and other lightweight “on the go” plastics (such as snack bags and candy wrappers) can quickly end up in the ocean. Consumers may throw them to the ground, or because they are shaped in a way that “catches the wind,” they may be picked up from garbage bins and float away.

Plastic eCommerce packaging - namely poly mailers - has two advantages over grocery bags and candy wrappers. First, they are thicker and heavier than grocery bags or candy wrappers and default to laying flat; therefore, they do not get picked up by the wind. Second, they are received and used at a home or office; therefore, they are unlikely to be tossed on a sidewalk as litter. As such, poly mailers that aren’t correctly recycled will end up in the landfill (a bad outcome) and not the ocean (a much worse outcome).

Now let’s consider the impact of plastic packaging in landfills. We hate landfills for a few reasons, mainly because every item sent there has reached its end of life. This end-of-life scenario is a complete waste of all the natural resources and human energy that went into whatever thing ends up there. Every item in the landfill is a missed opportunity to give new life to something. “Landfill culture” also wreaks havoc. The idea that you can readily dispose of something means people never truly have to come to grips with what they buy, use, and throw away every day.

Beyond this, there are two fundamental concerns related to landfills.

First, we are running out of landfill space. Bryan Staley, Ph.D., PE, president and chief executive officer of the Environmental Research & Education Foundation (EREF), believes we have 60 years of capacity left in our nation’s current landfill facilities. However, some states are facing more dire shortages. Seven states will run out of landfill space within five years and are shipping trash to faraway states - a costly and energy-intensive process. However, it is likely that as space diminishes, landfills will eventually become waste-to-energy plants, which accounts for just 13% of U.S. waste management, but is far more common across Europe, where land is at a premium.

Second, landfills are major GHG emitters and water polluters. When we deposit waste in a landfill, it undergoes an aerobic (with oxygen) decomposition stage generating little methane. Then, typically within less than one year, anaerobic conditions are established, and methane-producing bacteria begin to decompose the waste. This decomposition happens very gradually but still generates landfill gas (LFG), a natural byproduct of the decomposition of organic material in landfills. LFG comprises roughly 50% methane (the primary component of natural gas), 50% carbon dioxide (CO2), and a small amount of non-methane organic compounds. Methane is a potent greenhouse gas 28 to 36 times more effective than CO2 at trapping heat in the atmosphere over 100 years. Municipal solid waste (MSW) landfills are the third-largest source of human-related methane (after fossil fuel production and livestock farming) emissions in the United States, accounting for approximately 15.4% of these emissions in 2015. Note that this does not have to be the case. If used effectively, LFG can be a great source of energy. Today, 35% of waste ends up at landfills that capture methane for power, and the EPA is working on getting more landfills in this camp.

Now, back to materials and plastic in particular.

Today, with the current U.S. infrastructure, if packaging gets to a landfill rather than to a recycling or composting facility, we would prefer for it NOT to be biodegradable because we see these LFG emissions as the most significant negative impact of landfills. Nonbiodegradable materials in a landfill are relatively benign, given how gradually they degrade. Materials that biodegrade will more readily (though still slowly) undergo anaerobic digestion that creates methane. We recognize that these are essential points to reconsider as more and more U.S. landfills capture and use these emissions for energy or as more and more landfills move to WTE plants.

We have rated plastic as “moderate” given the multitude of considerations for the end of life for plastic eCommerce packaging. We can recycle plastic, and more and more, we can recycle it into itself. Additionally, most people currently have access to plastic recycling, though not all have access to curbside recycling. On the other hand, recycling rates are meager, though the trend is rising.

Paper - Good

On the other hand, paper is a bit of an end-of-life superhero. According to the EPA, more than 64% of the paper and paperboard generated as MSW was recycled in 2015. The CPA (Corrugated Packaging Alliance) states that over 90% of corrugated / cardboard is recycled. Paper can be recycled many times before its fibers become so short that we cannot remake it into any new paper product. We can also compost it, which is the required end-of-life if it contains any food or grease. If it ends up as litter (again, not typical for eCommerce packaging), it would biodegrade quickly and cause far less harm to ocean life.

Paper’s main downside is that if paper-based packaging is in a landfill, it is thicker and takes more room than its plastic counterparts. Also, it is likely to biodegrade - slowly but more rapidly than plastic - and generate landfill gas (LFG) emissions that are a significant concern for landfills.

Nevertheless, we have given paper a “good” rating regarding the end of life, ability, and the likelihood of being recycled or disposed of properly.

Bioplastic - Poor

Bioplastics have a few end-of-life paths. Something can be:

- Bio-based and recyclable, like Coca-Cola’s new HDPE PlantBottle. These end-of-life scenarios are not typical, particularly concerning flexible plastic used for eCommerce.

- Biodegradable and compostable, with a clear label that indicates it as such - either “Certified Compostable” or a #7 PLA (the PLA MUST be in the recycle sign for this to be the case, which confusingly is NOT recyclable but is compostable in industrial settings).

- It claims to be biodegradable through an additive that breaks plastic down into smaller pellets. These items are ideally recyclable (you would know if they have a recycle symbol and number on them) and, at worst, landfill-bound.

- It claims to be biodegradable with no proof or science behind it. Again, these items are ideally recyclable (you would know if they have a recycle symbol and number on them) and, at worse, landfill-bound.

We see three critical challenges related to biodegradable and compostable items.

First, typically, unless they are certified for home compost, compostable synthetic material (e.g., bioplastics such as PLA “7”) cannot just be tossed in your home compost bin or the dirt. These generally require microorganisms inside a professionally managed compost facility to consume them within a relatively short period. Unfortunately, less than 1% of the country has access to curbside collection of mixed compost, which, unlike standard composting facilities that only accept yard trimmings, are centers that take food scraps, bioplastics, paper, etc.

Second, compostable bioplastics are screwing up the recycling stream. PLA #7 is a perfect example. Many people send their PLA 7 (bio-based, compostable plastic) to the recycling facility even though it is not recyclable. At the MRF, this plastic will be sorted out and sent to the landfill or be mistaken for “normal” plastic during the sorting process. If an MRF sells a bale of plastic with too much PLA contamination, it could be rejected on delivery to its buyer, and the entire bale would be landfill-bound.

Third, while bioplastics are compostable, they don’t necessarily lead to great compost. Composting facilities that cater to organic farmers can’t accept these items. Bioplastics go through a process of polymerization, so they are “synthetic materials” and therefore don’t meet the USDA’s National Organic Program’s standards. Lindsay Fernandez-Salvador, a program manager at the Organic Materials Review Institute (OMRI), determines whether specific agricultural input products such as compost can be certified organic. She states that if compost has any synthetic materials, they disallow it. Additionally, industrial composting facilities are currently not well set up to process large volumes of bioplastics since these bioplastics were developed as a solution organic rather than synthetic waste. The facilities would need to be reconfigured to accommodate significant increases in bioplastics.

Finally, there is a commonly held misperception that people are doing good by buying biodegradable items and sending them to the landfill, where they will disappear quickly. As described above, biodegradable items will decompose in a landfill environment - slowly but more quickly than traditional plastic. However, that degradation leads to undesirable LFG emissions. So the end-of-life situation isn’t great in this scenario, and (making it even worse) the consumer leaves the experience with the sense that their action has been great for the planet.

Read More: We Could Sell You This Biodegradable Poly Mailer, But We Won’t

Note that new materials are emerging that biodegrade quickly by soaking the item in hot water. We are intrigued by these new technologies and may explore them going forward if they meet other essential aspects of our sustainable packaging framework.

The world of bioplastics and disposal options for bioplastics is still evolving and is currently fraught with confusion that can lead to ill consequences and waste stream contamination. Additionally, bioplastics are not yet designed to improve the nutrient content of compost and render it highly beneficial for the soil. Furthermore, few people still have access to curbside composting (for PLA and other compostable plastics).

As a result, we have given bioplastics a “poor” rating on end-of-life, ability, and the likelihood of being recycled or disposed of properly. However, we are confident this will improve over time and closely track forward progress in the industry!

Other Challenges of Plastic

Plasticizers such as phthalates and bisphenol A (BPA), which are added to the resin to reduce brittleness and promote plasticity, are two commonly cited examples of chemicals (some of which we know, some of which we don’t) that studies have shown to harm our health. In some uses (such as food or IV bags), it is evident how these toxins leach from the package to our bodies. Additionally, these chemicals are in our mattresses, furniture, cars - you name it. These chemicals are a very legitimate downside of plastic, and the toxic effects of bioplastic are unknown at this time. The short lifespan and minimal touch of eCommerce packaging likely make this more minor an issue. However, there is no focused research.

Finally, for many, the folks here at EcoEnclose included, the biggest issue with plastic is that its arrival into our industrial world has catapulted us into a “single-use” culture. From sandwich bags to plastic soda bottles to product packaging to disposable cutlery, inexpensive and highly versatile plastic has enabled companies to offer a host of goods that make our lives more convenient. Of course, many single-use items are not plastic - glass food jars, paper towels, paper bags, to name a small few. However, plastic seems to have helped establish this “convenience-driven” culture, which has led to an unbelievable amount of waste as the vast majority of goods we buy are either single-use or arrive with much disposable packaging.

What Does This Mean for Packaging?

Unfortunately, EcoEnclose cannot and does not attempt to provide you with a single, universal rule for what material to package your goods. EcoEnclose has instead focused on building a product line of packaging made with as much recycled content as possible. This process is the number one way to support eco-friendly strategies and business practices.

Thus, we carry diverse packaging solutions that span both recycled paper and recycled plastic (but do not currently include bioplastics, given that recycled bioplastics have not yet emerged).

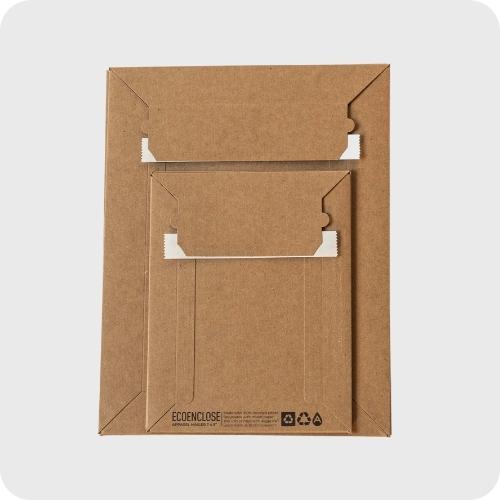

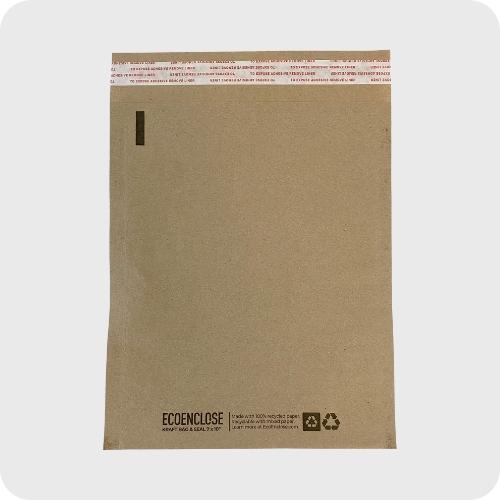

If you ship something light (like a t-shirt) that fits in a mailer, we are likely to advise you (from a pure sustainability perspective) to go with our 100% recycled poly mailers. If you ship prints or photos and need a stiffer, more protective option, we will likely direct you to our 100% recycled rigid mailers. If you send a collection of items, we will likely refer you to a 100% recycled custom shipping box. Finally, if you ship to a place where no one recycles (I hate to think of such a place!), we may encourage you to consider our plastic options, which are more stable and take up less room in landfills than paper counterparts.

Shop Recycled, Recyclable, Eco-Friendly Packaging

EcoEnclose is proud to offer an extensive line of sustainable packaging to meet your unique business needs. Shop some of our favorite solutions below.

Poly Mailers

100% recycled, 50% post-consumer waste. Thin-film recyclable, tear strip for easy opening, second adhesive strip for reuse.

Custom Shipping Boxes

100% recycled, 95% post-consumer waste. Fully customize style, size, strength, and branding, ensuring your product fits perfectly.

Apparel Paper Mailers

100% recycled, 97% post-consumer waste. Creasing for expandability and premium presentation. Ideal for shipping textiles.

Tissue Paper

100% recycled, 20% post-consumer waste. Certified sustainably sourced 10# paper protects against scuffing and dust.

Packaging Paper

100% recycled. Provides blocking and bracing support within a shipping box and can also be wrapped around products for light protection.

Custom Stickers

100% post-consumer waste paper stickers are available on our unique Zero Waste liner that is 100% recycled and curbside recyclable.

Kraft Bag & Seals

Curbside recyclable alternative to a clear poly bag. 30# Kraft paper with self-seal closure. 100% recycled, 60% post-consumer waste.

Custom Notecards

90-100% recycled. Available in various card stock colors and weights, beautifully printed CMYK. Convey your eco-friendly messaging.