The Impact of Pigments, Adhesives and Release Liners

Posted on Oct 21st 2021

EcoEnclose is on a mission to achieve true packaging circularity, in which packaging is recycled back into itself countless times, the need for virgin inputs is minimized, and any virgin inputs that are needed are produced in net neutral (if not regenerative!) ways.

While we are far from this end vision today, we, with the support and commitment of our incredible EcoAlly Community, are making slow and steady strides forward.

Specifically, we celebrate small and large achievements: Our ability to offer 100% recycled paper mailers and shipping boxes, our introduction of 100% recycled poly mailers, our progress from a 32.6% bubble mailer to a 50% recycled bubble mailer (with 10% post-consumer recycled content), seeing consumers take advantage of our poly film take back program, the introduction of recycled content into GreenWrap, and so much more.

While we celebrate these wins, we - in no way - have our head in the sand.

We recognize how far we are from our ultimate vision, and the challenges and shortcomings of our current offerings.

One aspect of that, which we talk and write about frequently, is the impact of "the little things" on our packaging. This includes inks, pigments, adhesives and seal strips. Across all of our packaging options, these "little things" aren't generally where we want them to be.

Some examples of areas we still need to improve on include:

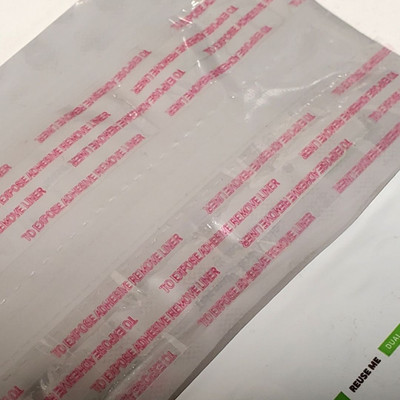

- Mailer Seal Strip Release Liners: Our mailers have self sealing strips on them, so they can be sealed shut without the need for tape. These seal strips are covered by a release liner. Currently, across all of our mailers, these release liners are virgin. For our paper mailers, these release liners are made with virgin, supercalendered, silicone coated paper. For our poly and bubble mailers, these release liners are made with virgin polypropylene (BOPP). Unfortunately, these release liners are not only made with virgin content, they are also unrecyclable. EcoEnclose currently offers a unique line of stickers and labels that come on a Zero Waste release liner. Unlike all other release liners on the market today, this Zero Waste option is 100% recycled and curbside recyclable, as it does not contain a silicone coating. We are actively exploring ways to apply these release liners to our mailer seal strips to address this current shortcoming of our mailer offerings.

- Pigments In Poly and Bubble Mailers: The film used to create all poly and bubble mailers is comprised of raw resins, dyed resins to ensure an opaque bag, and additives that help achieve the right level of seal strength. The primary resin used in our poly mailers accounts for over 98% of the material and is 100% recycled, of which 50% is post-consumer waste. Additives and colorant resins that are mixed into these raw resins can account for up to 2% of the overall weight of the material, and any polymers in these are made with virgin content. We certainly see opportunities to develop more sustainable additives and colorants, by deriving them from more regenerative sources and replacing virgin polymers with recycled alternatives.

- Inks on Our Mailers: All of our mailers, including our paper and our poly mailers, are printed with mailer dimensions and eco-related information. Over the last two years, we've been able to print our stock mailers with black Algae Ink. By transitioning from standard water-based black ink to ink whose pigments are made with algae waste, we've made great progress in this area. However, even Algae Ink contains additives, which account for about 20% of printing ink. These additives support the ink's adhesion, drying, and reducing smudging. When customers order custom-printed mailers or boxes, their packaging is printed with water-based inks. While these water-based inks are a much more eco-friendly alternative than solvent-based inks, their pigments are typically derived from fossil fuels and other non-renewable resources, and they also contain additives to support with the printing, drying and print quality. Pigments and additives together account for about 35% of the weight of printing ink. We see an opportunity to make ecological advancements in the inks used in our packaging, deriving them from more regenerative sources and ensuring that they don't negatively impact the end of life and recyclability of the substrates they are applied to.

- Adhesives: EcoEnclose uses several different types of adhesives to convert and seal our mailers and boxes. Our main three categories of adhesives include hot melt, acrylic emulsion and starch based. These adhesives are made from a variety of inputs, including virgin polymers. Thus far, our focus has been on evaluating adhesives to ensure they separate easily in the paper repulping process, so they don't negatively impact the recyclability of the package they are used on. Over time, we see opportunities to improve our adhesives further, deriving them from more regenerative sources, ensuring they are safe and healthy for manufacturers to work with, identifying opportunities to use less adhesive for each mailer, and further reducing the impact of adhesive on the remanufacturing process so that the resulting recycled content can be of higher and more durable quality.

While most consumers and brands do not consider packaging to this level of detail, we - and the amazing EcoAllies we work with - actually do! Because of this, we provide a highly detailed Bill of Materials for all of our product categories. This Bill of Materials lists information on the inks, pigments, adhesives and release liners used across our products.

While we at EcoEnclose recognize that these "little things" aren't where we want them to be and that there is much opportunity for improvement, we are also constantly balancing them with bigger picture opportunities for advancement in sustainable packaging. As we think about prioritizing our limited time and resources, we know that introducing recycled content into a line that is currently made with virgin materials (such as our glassine bags) or upping recycling content levels where we aren't yet at 100% recycled (such as our bubble mailers) will be a bigger and more immediate step forward in our journey towards circularity than an improvement in our adhesives or colorants would be. Because of this, we invest far more of our energy into these larger improvement opportunities than these more incremental details.

We also recognize that advancements in these "smaller components" of packaging require deep, highly technical expertise. As a result, we seek opportunities to work and partner with experts in these fields. When scientists, private companies, university groups, or any other experts make a breakthrough in the field of adhesives, inks and pigments, we are eager to test these across our manufacturing lines and help make them commercially viable as quickly as possible. In this way, we hope EcoEnclose can serve as a go-to-market partner for individuals and groups out there who are trying to make advancements in these industries, the way we supported Living Ink Technologies to make their patented algae ink technology available broadly.

If you are as interested in these seemingly small aspects of packaging as we are, or if you are actively working on technology development in the world of adhesives, inks and pigments, we would love to connect and see how we can work together. Contact us anytime at hello@ecoenclose.com.