Recycled Content Versus Bioplastics

Posted on May 25th 2022

Recycled Content Versus Bioplastics

Many of us have heard of bioplastics - polymers made from bio-based sources OR that are biodegradable, or both. We recently completed a comprehensive review and research of the most biopolymers and dissolvable plastics on the market. Our goal of that research? To determine where bioplastics fit into our Sustainable Packaging Framework.

At EcoEnclose, we are firm believers in science-based research and decision-making for creating and verifying sustainable packaging. We used this approach when reviewing biopolymers, and determining whether we would consider using them in our own product suite.

The short answer to our research question?

Read on to learn about why we still value recycled content (specifically post consumer waste) as the #1 input material to prioritize for sustainable packaging.

In order to gain a holistic understanding of the impact of a material, we need to consider its entire lifespan - from production, to end of life. This chart breaks down the impacts and considerations for the 3 main aspects of a life cycle: source inputs, use case/functionality, and end of life.

Recycled Plastic versus Bio-based and Biodegradable Plastic

Source Inputs

Winner: Recycled Content

Using recycled content (plastic or paper) as a source input for packaging, instead of a virgin (0% recycled) source input material, often reduces the impact of your product significantly! The net ecological benefits of recycling are clear: Recycled aluminum saves 95% of energy, recycled paper saves 60%, and recycled plastic and glass save about 30-50%.

While recycled plastics pull from existing materials, source inputs for bio-based plastics are almost always virgin - meaning they are created and drawn from natural resources to produce material for use. In packaging, it’s often single-use.

Bio-based plastics also have a larger water footprint and impact on freshwater systems - since they’re formed from (typically industrial monocrop) crops grown at high volumes, which require fertilizer and pesticide use and expanses of land for cultivating.

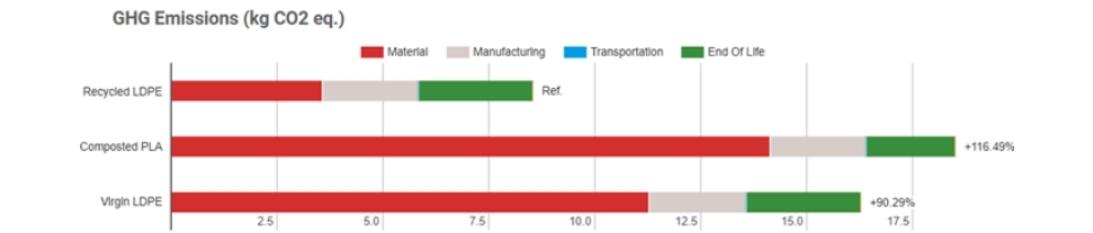

GHG emissions are typically higher for bio-based plastics than recycled and virgin plastics. The bulk of this GHG footprint comes from the production of the polymer itself - in this case, PLA is made from starches, typically corn. Corn requires large amounts of energy, space, and water to grow industrially. Turning the corn starch (once cultivated) into a polymer requires considerable energy.

The source material used to create the bio-based polymer can vary depending on the biopolymer. Still, it is typically a starch or sugar-producing material - like corn, beets, or sugarcane. These crops usually require large swathes of land to grow and, unfortunately, can (if not sourced responsibly) expand into endangered habitats or require clear-cutting of critical habitats to meet their demand.

In comparison, recycled plastics do not need farmland to be produced. Using recycled plastics also opens the opportunity to partner with suppliers who source ocean plastics or otherwise clean up and divert plastic waste from critical habitats - building a market and demand for these materials.

Using recycled content instead of bio-based plastics can help several environmental goals: energy use, carbon footprint, using waste materials and diverting landfill waste, habitat protection, and protecting endangered species.

Function

Winner: Recycled Content

Recycled plastics - in terms of use and functionality - can usually be an exact replacement for virgin plastics, meaning they perform the same or similar.

Drop-in bioplastics (bio-based but not biodegradable, meant to be recycled) function the same as virgin or recycled plastics and are not structurally different from standard plastics.

Biodegradable plastics (meant to be composted or biodegraded at the end of life) typically have a shorter shelf-life than recycled or virgin petroleum-based plastics. This shorter shelf-life should be a consideration for any use cases that require (or prefer) keeping large amounts of inventory on hand at a time.

End-of-Life

Winner: Recycled Content

Using recycled content in plastic does not hinder its recyclability at the end of its life. As always, though, the materials accepted in a curbside recycling program are determined by each person’s waste and recycling hauler.

While the acceptable plastics in curbside recycling programs vary, it’s important to note that (as of 2021) 73% of Americans have access to curbside recycling pickups.

Biodegradable plastics are often designed to be composted in industrial composting streams - managed by a compost hauler or municipality. These bioplastics are less frequently backyard compostable (but can be - check with the manufacturer.)

However, just because a bioplastic has achieved a certification verifying its ability to be industrially composted (i.e., BPI or ASTM certification) does not guarantee that each industrial compost hauler will accept them. This is similar to each recycler’s ability to choose what materials they take into their facilities. We studied compost haulers and their acceptable materials in America's 20 most populous cities. Only two would take bioplastic eCommerce packaging if it clearly stated and showed the relevant BPI certification.

Given these introductory accessibility rates, recyclable plastics win here.

At EcoEnclose, we always design packaging for recyclability to ensure it will make its way back into a source material stream. Then, we can continue making new packaging out of old packaging, which can become packaging again!

Summary

We believe it’s important to not only do deep and thoughtful research on new materials in the packaging space, but to also share our findings and our decision-making criteria with our community. We hope this transparency allows you to understand the structure in which we consider materials, as well as the impacts that we look for in determining the benefits and drawbacks of them.