Minimum Order Quantities: What They Are and Why We Have Them

Posted on May 7th 2021

Why Minimum Order Quantity Exists for Custom Packaging

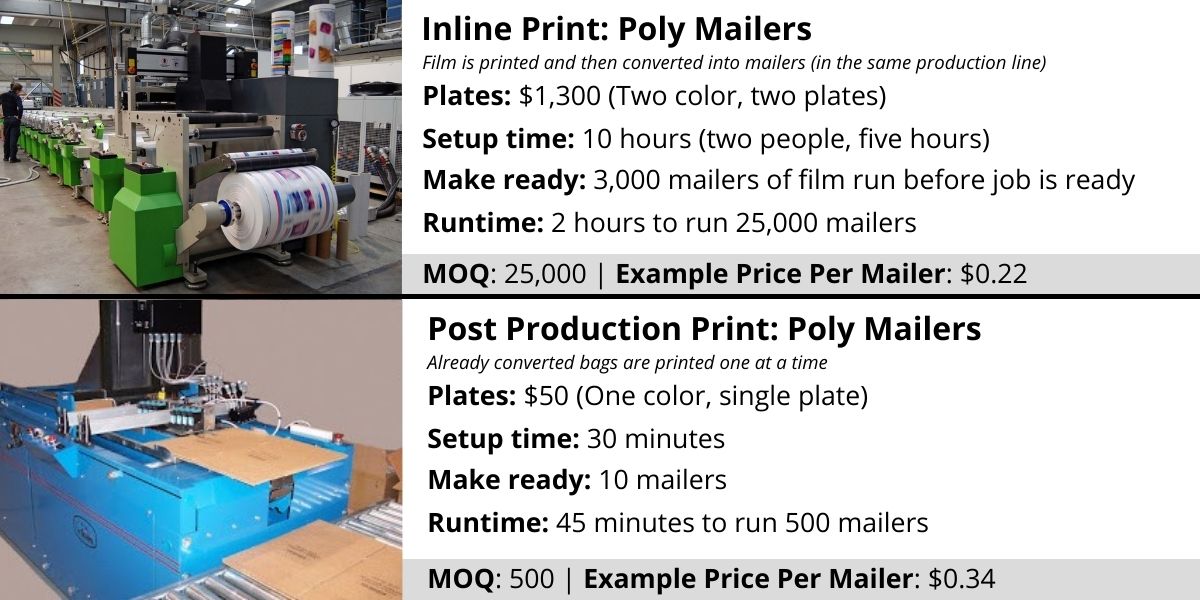

Post production printing has low minimum order quantities (usually starting around 500 units) but requires more limited print capabilities and higher unit pricing. Inline printing has much higher minimum order quantities, but offers more expansive print capabilities and lower unit pricing. This is because of the relationship between the setup time, complexity, materials waste and run time. The following visual shows one comparison to help illustrate.

What is an MOQ?

“MOQ”, or minimum order quantity, refers to the fewest number of units required to be purchased at one time in order to place an order. While MOQs exist in almost every industry, they tend to be most common in the world of customized goods. For EcoEnclose customers, they come up most frequently when customers are exploring custom branded packaging (and other customizations such as custom sizes or custom features).

In a perfect world, we and any other company could provide you with the items your business needs in the exact quantity that you need them. Unfortunately this is not always economically or logistically feasible.

The main reason for this is due to the upfront fixed costs associated with setting up a custom print job. An MOQ ensures that this initial resource investment required to set up a custom print job is worthwhile in the end, because enough units are being sold to cover that upfront cost.

Typically, the more complex and resource intensive the set up of a job is, the higher the MOQ will be. This same rationale is also why you’ll often see fairly steep discounts at certain volume thresholds. The larger the order size, the lower the per unit price needs to be to still cover the upfront cost of setting up the job.

Why Are EcoEnclose’s MOQs for Branded Packaging So Varied?

EcoEnclose offers a variety of different custom branded products - mailers, shipping boxes, stickers, notecards and more. The MOQ on custom branded shipping boxes is just 100, while the MOQ for custom mailers is 500 and the MOQ for custom tissue paper is 4,800.

Why the difference? Before we answer this question, let’s tackle two others concepts:

- What is the difference between digital printing and analog printing?

- What is the difference between post-production and inline printing?

Analog versus Digital Printing

Analog Printing: Analog printing involves the creation of a master image on an “image carrier” (such as a printing plate or a screen). Ink is transferred to the image carrier and then to the substrate using processes such as flexography, offset and screen.

Digital Printing: Digital printing involves the transferring of an electronic image file to a printer. The printer takes the design data and converts it into a printable image utilizing pixels and dots, allowing it to print directly on the substrate.

| Analog (Flexo or Offset) Printing | Digital Printing |

Bottom line: Longer and more complex set up. Lower per unit cost. Higher quality prints. |

Bottom line: Minimal set up. Higher per unit costs. Lower quality prints. |

But wait, there’s more. There are also two different types of analog printing services that we offer: Post-production vs inline printing

Post-Production Printing: A post production print (sometimes called an overprint or direct to package print) means that the package was fully produced or converted first, and then printed.

Inline Printing: Inline or pre-production printing means that the packaging material (usually on large rolls) is printed and is then converted into packaging, often in the same manufacturing line.

| Post Production | In-Line |

Bottom line: Lower MOQs, higher per unit costs, more print limitations |

Bottom line: High MOQs, lower per unit costs, broader print capabilities |

Why Are MOQs for Production or “Inline” Runs So High?

Our MOQs vary based on digital vs analog and inline versus post-production printing. And, in some cases we’re not able to (yet) offer post-production or digital printing at all.

This table is an illustrative example of what we offer and the associated MOQ. Note that for the most current information on our in-line and post-production capabilities and minimum order quantities, please check out the following two pages:

| Packaging Category | Digital Printing | Post-Production Flexo Printing | In-Line Printing |

| Shipping Boxes | MOQ: 100 | MOQ: 100 | MOQ: 5,000 in most cases |

| Paper Mailers | MOQ: 250 | MOQ: 500 (or multiple of a case) | MOQ: 5,000-15,000 |

| Poly Mailers | N/A | MOQ: 500 (or one case if case is more than 500 mailers) | MOQ: 25,000 |

| Bubble Mailers | N/A | N/A | MOQ: 25,000 |

| Glassine Bags | MOQ: 250 | MOQ: 500 (or multiple of a case) | MOQ: 250,000 |

| Poly Bags | N/A | N/A | MOQ: 50,000 |

| Tissue Paper | N/A | N/A | MOQ: 4,800 sheets |

| GreenWrap | N/A | N/A | 24 cases |

| Retail Boxes | N/A | N/A | MOQ: 10,000 |

| Paper Tubes | N/A | N/A | MOQ: 5,000 |

As you can see from the above chart, the minimums for inline printing can be very high.

This is because of the relationship between the setup time, complexity and waste and the run time.

For example, in order to produce a two-color print of 25,000 10x13 poly mailers:

- Two printing plates (totaling $1,300.00 cost) must be purchased

- The job is set up on a massive web-fed flexographic printer. This setup might take 2 people about 5 hours and utilize 3000 mailers worth of material before the set up achieves the right pressure, ink coverage and registration.

- Finally, the job is run and it may take only 2 hours to complete the printing and conversion of those 25,000 mailers

In this scenario, the minimum order quantity is 25,000 because if it were anything less it would not cover the cost of that complex set up (or would mean that the per mailer price would have to be set so laughably high that no company would take advantage of the lower minimums).

While the exact math looks different for each packaging category, the basic concept is the same - when packaging is printed before it is converted, the up front set up is harder and more expensive, meaning that a higher MOQ must be set.

Why Do Some Companies Have No or Very Low MOQs?

We know that some packaging providers out there have no or very low MOQs. This is driven by a few things:

- A highly automated image to print process, which removes any interaction with the customer on artwork proofing. By eliminating the proofing step (and simply having a customer approve a digital proof at checkout), the provider drastically reduces this portion of the prepress setup time and cost.

- Gang run technology, in which multiple jobs are all queued up after each other, with fully automated transition from one job to the next. In this approach, there is less attention to set up and the print quality at setup for each individual job, which allows for a much lower setup cost.

- Digital (versus analog) printing processes. Digital printing means that while the per unit cost is higher, because the printing process is slower and the ink is more expensive, the make-ready (or time to get the job set up) can be virtually zero. You’ll often find that with providers that have a very low MOQ, they aren’t able to offer competitive pricing at higher volumes because they are designed to best serve companies that only need 50-100 packages at a time, and their printing strategies do not scale efficiently.

MOQs for EcoEnclose and PCW

It is important to note that the concept of an MOQ exists beyond custom branded packaging as well! For example, EcoEnclose faces MOQs all the time, particularly because of our commitment to circularity and recycled packaging. When working with our supply chain to source 100% recycled film for our poly mailers, we have to commit to very high volumes in order to secure this 100% recycled film supply at a reasonable price point. In fact, in many ways, our willingness to commit to these volumes, even when a new eco-friendly product isn’t necessarily fully proven in the marketplace, has helped us constantly push our packaging options forward. Had we hesitated or been unwilling to make these large investments in high minimum order quantities, we would not have incentivized our supply chain to take risks with the recycled content levels we demanded.